If you’ve been mountain biking for long, you’ve heard of Hope Tech components. This legendary brand out of Barnoldswick, England, has been designing and manufacturing their storied hubs and brakes in-house since the year before I was born, back in 1989.

That was a long time ago, but long timelines are what this company is known for. Their previous hub, the Pro 4 EVO, was launched in early 2016, and is still a mainstay six years later.

“When someone buys one of our hubs I want it to last them five years . . . They shouldn’t need another hub until the new one comes out . . . My philosophy has always been to build something that lasts with the minimum amount of weight you need to put into it to make it reliable,” said Owen Hardisty, a design engineer with Hope, in their Pro 4 launch video. And, with the release of the Pro 5, that time is now!

Updates to the Pro 5

With that hub Hope felt like they reached their weight and durability goals, so with the Pro 5 they set their sights on a few other fronts. One of the most visible ones is a new seal design on the hub driver.

Both the Pro 5 (left) and Pro 4 (right) feature a green dirt seal, but they are arranged slightly differently.

On both the Pro 4 and Pro 5, the green plastic portion of the seal is securely pressed into the hub shell, so much so that it makes it fairly difficult to pull the freehub off the hub shell. That effectively seals water and dirt out on the outside perimeter of the seal. It is the inner side of the seal, however, where changes happen with the Pro 5. Here, you have to balance making a seal that will keep schmutz out of your pawls and drive ring, but also one that won’t result in a bunch of drag.

The groove on the Pro 4 driver where the seal sits

On the Pro 4, this is done by overlapping the seal in a groove on the freehub. It’s free floating, so it shouldn’t make any drag, and there is overlap so it’s not exactly open to the elements, but I wouldn’t call it “fully” sealed. The Pro 5 addresses the same question by adding two new elements: an o-ring and black aluminum seal cover. The green seal still floats freely around the free hub, but the black seal cover presses on to the o-ring. This gives you that same free-floating situation on the inside, but with a smaller, more circuitous avenue for entry, making it harder for outside elements to make their way in. I think it also looks a lot nicer than before (not that you’ll be seeing it once the cassette is on.)

The new labyrinth seal on the Hope Pro 5. Note how the black cover (partially cut away) helps create a more secure seal.

Although the new design does look to be a better seal, I didn’t quite understand how it reduced drag in any way. From the looks of it, neither of them contacts the driver, so neither should result in any drag. When I asked Hope about this, they said that in fact the Pro 4 seal can make contact with the driver, whereas the new Pro 5 seal will not under normal operation. Either way, any drag coming from these seals will be negligible.

Pawls and springs

The Hope Pro 4 has 44 points of engagement, which is accomplished by running 4 pawls that all engage at the same time on a 44 tooth drive ring. Pushing them into place are big, stiff springs, which is why Pro 4 hubs are so loud. It’s a bombproof design and is part of the reason why the Hope Pro4 is widely lauded as being so reliable.

Hope Pro 4 pawls and springs.

But does something need to be bombproof to be durable? No. Take a look at Industry Nine’s Hydra hubs, which use 6 pawls that engage one at a time on a 115 tooth ring to give you 690 points of engagement. You probably wouldn’t want to tow a train with it, but it works great.

With the Pro 5, Hope has bumped up the engagement to 108 points, (every 3.3 degrees), by using 6 pawls that engage in two separate phases within a 54 tooth ring. Two times 54 is 108. There’s lots of thoughts about whether more engagement is better. I think a lot of people today would argue that 44 is too few, but that 108 is just fine. Chris King’s hubs, for example, have 72 points of engagement. I will say that in my own experience, I just get used to whatever I’m running, after which it doesn’t seem to affect my ride whatsoever.

Hope Pro 5 pawls and springs.

All else equal, having more pawls rubbing on the drive ring would result in more drag, so what else have they done to reduce it? The construction of the pawls is the same, but they’ve re-designed the springs that push the pawls up into the drive ring. They are now the same width as the pawl, whereas the previous ones were more narrow. Hope claims this change will make the pressure application more even and decrease wear.

There is also now a cut out in the center of the spring, which actually reduces the amount of force the spring applies to the pawl. This is where I suspect the bulk of reduction in drag comes from. For those of you who don’t love loud hubs, it also results in a much quieter hub.

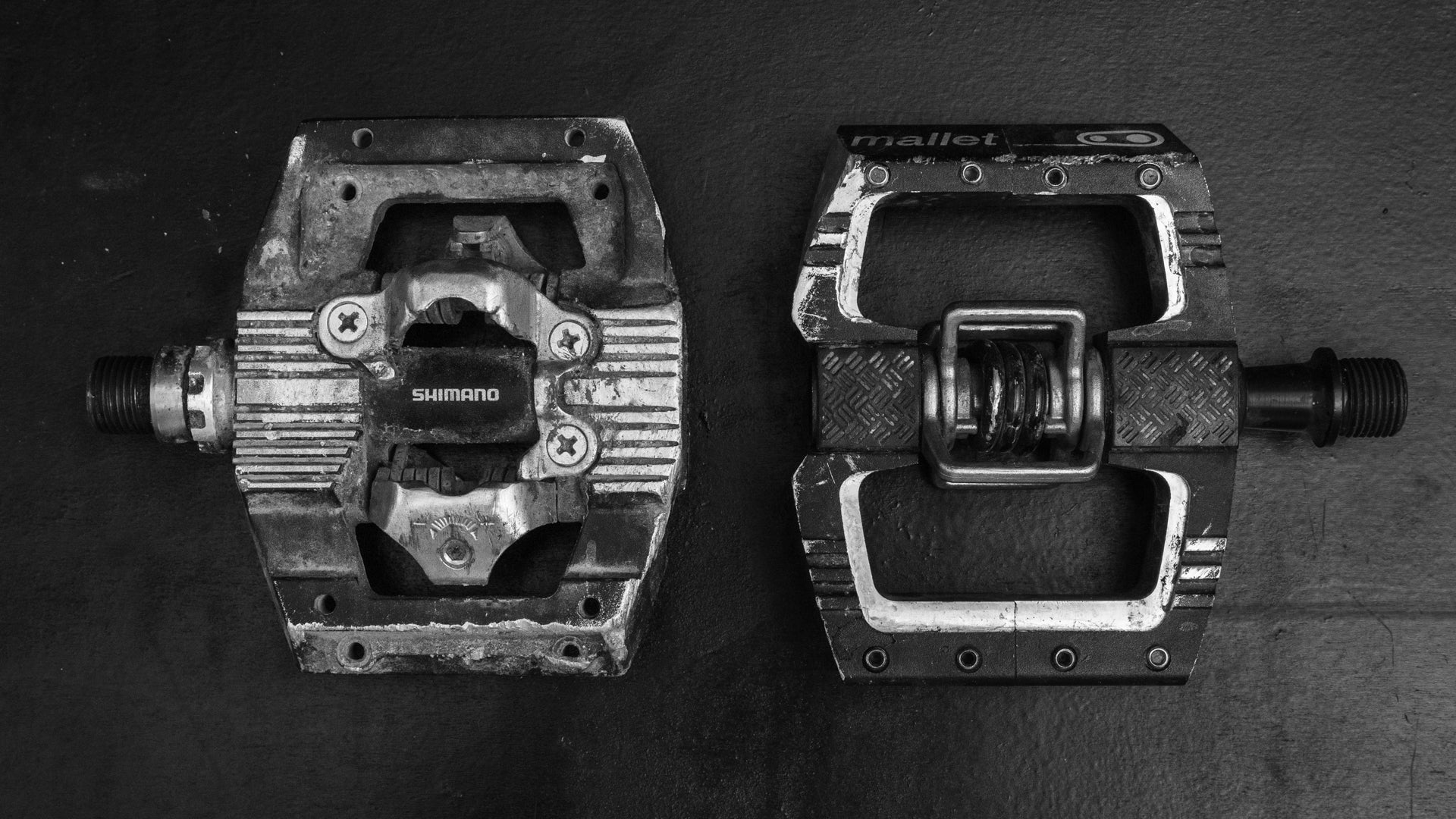

The Hope Pro 5 springs on the left and Pro 4 springs on the right. The pawls are identical.

Other improvements

Reducing drag isn’t the only place Hope focused their attention when redesigning this hub. Of particular note are the larger bearings they’ve managed to fit into the driver. They accomplished this by stepping down the outer diameter of the hub axle underneath the driver.

The new axle on the Hope Pro 5 (left) vs the Pro 4 (right)

This allows for a bearing where the outer diameter is the same, but the inner diameter is smaller, and the whole bearing is wider, so the actual balls in the bearing are bigger. That means longer life for the bearings, so you get longer service intervals, so there is less headache for you! As per usual with Hope, it’s easy to service these hubs at home without any proprietary tools.

The 15x26x7mm bearing in the Hope Pro 5 driver is larger than the 17x26x5mm bearing in the Pro 4.

Pro 5 hubs come in every hub standard you could want, and Hope offers different end-caps to convert them where possible. There’s 6-bolt and centerlock, any number of spokes holes you want, and a bunch of different colors. There’s also an e-bike version where all six pawls engage simultaneously for a higher max torque rating, and which uses a stainless steel driver for increased durability.

Drag test conclusion

If you watched our video about this hub, you saw that we tested the drag of the two hubs back-to-back. There is no contest when you spin the Pro 5 vs the pro 4 in a wheel stand; the pro 5 spins for a significantly longer time. We figured it would be the same in the real world, and that was the question we set out to answer.

Our methodology was as follows:

- We used one bicycle, and only swapped out the rear wheels.

- We built both rear wheels the same way with identical rims, spokes, nipples, inner tubes, and new tires.

- We removed the grease from the pawls and drive ring.

- We inflated both tires (with inner tubes inside) to 25 psi with the same pump.

- We found a long paved downhill slope that evened out before heading back up hill at a lower grade.

- We made a start line on the downhill where our rider placed their front wheel on each trial.

- They raised their feet, after which gravity started them rolling. They entered a speed tuck, and put their feet down when they stopped moving (just under 300 feet, ~85 meters)

- We repeated each test three times, and took the average.

As experiments often do, the results surprised us. In this case, it surprised us a lot. In averaging out our three tests of each rim, the Hope Pro 4 traveled 282.3 feet, whereas the Pro 5 traveled 275.85 feet. They both did so in an average of just under 36 seconds—the Pro 4 in 35.9 seconds and the Pro 5 in 35.19 seconds. Their average max speeds, as recorded by Strava, were almost identical: 35.23 mph for the Pro 4, 35.2 mph for the Pro 5.

The Sprag, doing some testing

Not only did the Pro 5 not roll further or faster than the Pro 4, it actually rolled less distance, without reaching the same max speed. That said, it was all so close as to almost be a tie, but it was a surprising result nonetheless. We expected the new hub to come out way on top.

Now, what we are doing here amounts to elementary school science. It is not rigorous by any measure. I want to take a quick look at what we could have done better before we conclude.

Firstly, we could have completely eliminated the rear brake rotor as a variable by removing it. After our first Pro 5 test, I double checked that it wasn’t rubbing—it wasn’t at all. But sometimes when you sit on your bike things shift, and I can’t rule out that it might have rubbed a little on the Pro 5 and not the Pro 4. The most controlled way to do it would have been to remove it.

Secondly, was tire selection. We used two brand new, same-model tires, both with inner tubes to prevent any leaking, both inflated to 25 psi with the same tire pump. In retrospect, the most controlled way of doing it would have been to use the exact same tire for both wheels, and then double checked the PSI with an electric pressure gauge.

Third, the wind. In the morning, when we tested the Pro 4, it was completely quiet. The wind picked up a little in the afternoon when we tested the Pro 5. After the first Pro 5 test, we made sure that it was calm before doing a run. I’m pretty confident we did that successfully; we were in a protected valley and there were trees everywhere to gauge the wind. But still, it wasn’t perfectly controlled.

Here’s the thing though—all these variables were controlled to a much greater extent than they ever would in real world riding conditions. And that, after all, was what we set out to determine: does the decreased drag on the Pro 5 have real world riding implications?

The answer, it seems to me, is no. If one or two psi, or an imperceptible amount of rotor rub, or a different batch of otherwise identical tires can erase any differences these two hubs have in terms of rolling resistance, then when you’re actually on trail, it’s just not going to matter.

The Sprag, enjoying some air time.

Does that mean you shouldn’t buy the Hope Pro 5? No, not at all. The Pro 5 builds upon one of the most successful hubs we’ve ever sold, the Pro 4, and makes it better both objectively, by using a bigger bearing in the freehub and a better seal, and subjectively, by more than doubling the engagement and by making it quieter! Want to combat pedal kick by having less engagement? Run the steel e-bike driver or pull out three of your palls and get 54 points of engagement. Want a louder hub? Run a lighter hub grease!

You are still getting an incredible hub that was made by people as passionate about bikes as you, for a price that beats much of the competition. I think the takeaway from today is that if you keep your bearings in good working order, you needn’t stress about drag in your hub. And, of course, that the Pro 5 is a phenomenal hub that builds upon the successes of the Pro 4. Now, if you want to build up your own awesome hand-built wheelset, just hit this link and head on over to our Custom Wheel Builder tool!