Bellingham, Washington, the hometown of several long-standing mountain bike brands that you probably recognize; from Transition Bikes, to Canfield Brothers, Kona Bikes, and Schwalbe Tires, the list is extensive. Located just an hour and a half south of Vancouver, BC, the birthplace of “Northshore” style riding, and three hours south of the mountain bike mecca known as Whistler Bike Park, it is the perfect testing grounds for all things MTB.

It is therefore no surprise that nascent mountain bike component manufacturer ANVL was born here. Formed by a few key individuals as a side project to Transition Bikes, this hometown brand draws its inspiration, both in form and function, from the artisan blacksmiths of old and their dedication to the highly refined and painstakingly crafted tools of their trade. The relatively small company is able to dedicate their extensive experience in mountain biking as well as design and engineering to produce components with gorgeous lines that fulfill their desire to maintain the highest degree of performance.

ANVL makes all the components you need to set up your cockpit, as well as a selection of saddles that we are absolutely stoked on. Located just around the corner from Fanatik Bike Co. we took the opportunity to approach the people behind this brand to learn a bit more about the company, their design philosophy, and their goals for the future. Kyle Young is a co-founder of Transition Bikes and ANVL components, and Darrin Seeds is the industrial designer for both companies and “man with the plan” at ANVL. We’ve also taken some time to detail our favorite of ANVL’s components, which many of us here at the shop use day in and day out.

What was the impetus that brought ANVL to existence?

Kyle: There was a combination of things that drove us to create ANVL. We have always designed our own components, but historically we branded them under Transition Bikes, with the main goal being to create rad, affordable components for our various build kits. We never intended on selling the parts in the aftermarket. This always limited what we could create as keeping the cost low was a key point in making affordable build kits.

Eventually we just got tired of that strategy. There are plenty of component makers producing solid parts with huge brand value. They are able to offer ridiculous pricing because they manufacture large quantities for the OEM market. It made sense to accept that and use those parts on our bikes. This left us thinking “hey, sweet, now we can design the stem we’ve always wanted, and the pedals, and saddle, etc. without regard to cost.”

Around this time we brought Darrin onto the team; he's an incredible designer so we thought “cool, let's really go nuts and make a brand around this.” We debated long and hard whether we wanted to make this part of Transition or let it be it's own thing. Ultimately ANVL was born as an entity on its own. We really didn't want to pigeonhole the parts as a "house brand,” because they are far more than that.

Creating ANVL has allowed us to think about the entire process of building homogeneity between the designs of the parts and the actual brand. It also allowed us to tell the story the way we wanted without the backdrop of Transition Bikes clouding it up. A bonus was that as a stand alone brand, ANVL attracts a wide variety of consumers looking for high end mtb components, regardless of what make of bike they ride.

Who is behind ANVL, and what experience do they bring to the table, both in terms of riding and design/manufacturing background?

Darrin: ANVL Components are created by the same crew that brings you Transition Bikes, so our passion and experience in the bike industry runs deep. The product, branding, and graphic design direction has been developed by myself, Darrin Seeds.

I studied Industrial Design at Western Washington University right here in Bellingham. Shortly after moving up here I became aware of the mountain bike scene and quickly became addicted to the sport. Even in college I was designing bikes and components for school projects. This was right around the time Kyle and Kevin were down in Seattle getting their first bikes into production.

After graduating I moved to Portland Oregon to take a job with Gerber Knives. Working there I gained several years of design and manufacturing experience designing high precision tools for our military, outdoor enthusiasts, and Bear Grylls! I also became fully immersed in riding and racing mountain bikes, moving my way up the ranks to the pro category. Fast forward 6 years and I finally found myself back in B'ham with my dream job. One of the first tasks Kyle and Kevin gave me was creating a new component brand with a full line of products. From there, ANVL was born.

On your website you talk about basing your product designs on your vision for the future of our sport. Can you elaborate on this vision, and how ANVL hopes to shape that future?

Darrin: We all ride mountain bikes a lot, and strive to create solutions that meet the specific needs of riding a mountain bike hard. Our location here in the PNW allows us to push these parts to the limit, and pinpoint exactly where improvements can be made. When it comes to the components that riders choose there are tons of options out there. In the case of touch points like grips, saddles and pedals there's always contention and personal preference, which is probably the single hardest thing we face internally during the design and development phase. What it comes down to is a lot of prototyping, a lot of testing, and in the end, some level of compromise between us in determining what will work best for the most people.

With the advancements in materials and the refinements taking place in the mountain bike industry and within Transition, we work hard to design components that match that level of form and function. Products that can stand up to the way we ride, are simple to use, look rad, and offer a great value. One of our biggest goals is making products that you will not only fall in love with, but be able to take from bike to bike, because they are that good and that durable.

For those of us not versed in manufacturing and design, what are the stages that a new component undergoes, starting at their conception?

Darrin: It's virtually exactly the same as the way we develop our bikes. Drawing on the immense rider experience in our building including Kyle, Kevin, Lars Sternberg, and our Product Manager Sam Burkhardt, there's no shortage of valuable direction and feedback.

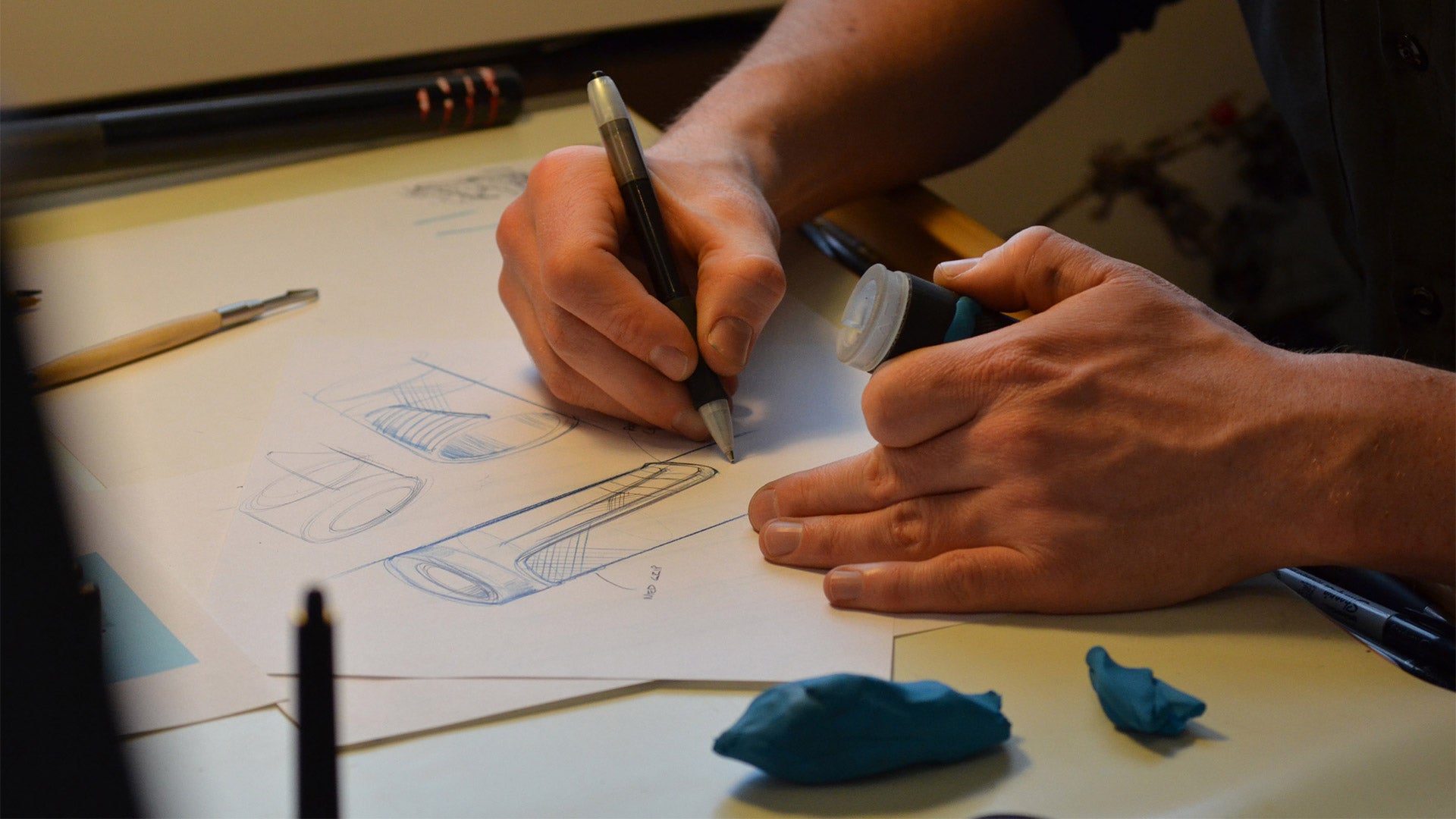

We start by going to the drawing board with a list of things we want. From there we lock down the geometry hardpoints and functional needs, like weight targets and materials. Then I sit down with with pencil and paper and create rough concepts that we review as a group, and refine, refine, refine. Next I create 2D realistic renderings before diving into 3D design.

The 3D CAD design is where a lot of the details are fleshed out, especially combined with our 3D printer. That tool allows us to quickly create a physical object which we use to test fit and feel. Kyle goes through and finalizes my CAD drawings for DFM (design for manufacturing) in conjunction with engineers from our sourcing partners. Once we are confident in the design direction we spend quite a bit of time in prototyping and testing.

While we are out ripping on the prototypes, I develop the finishes, colors, graphics, and packaging. Once we complete testing and make any needed refinements, all of the necessary tooling is created and it all goes to production. Depending on the product the whole process takes on average about 18 months.

Can you give us any hints or sneak previews on upcoming bits and pieces?

Kyle: Without giving too much info....we're working on a few new options that we think are pretty neat. Our goal remains to make products at the highest level of quality and function, designed for top level enthusiast riders. As such, we will continue to focus on the upper end segment. This year will likely see a ton of refinement plus a couple new products. Stay tuned!

There has been a good bit of back and forth on the merits of 35mm handlebar clamps. You guys only make stems and bars using this standard, can you tell us why you went that route?

Kyle: This was a long debated topic when we embarked on handlebar development. At the end of the day we believe that there is no single perfect product for everybody. We need choices and variety; it's the spice of life.

That being said, all the testing and prototyping that we’ve done has led us to the conclusion that, when designed correctly, a 35mm bar/stem interface can provide the right balance of stiffness and comfort for aggressive riding. Our experience with first gen 35mm handlebars was too much stiffness. From our analysis this was caused by the location of the bends and tapers in the bar. We did some pretty extensive overlay analysis and designed our bends to not only put the flex in the right place, but also give our bars a smoother, more aesthetically pleasing taper zone. An added benefit is that with the larger diameter, you can get a better looking match with the bikes being designed these days. The forms on the bike are getting bigger and more sculpted and we really like how the bigger interface matches the front end of current bikes.

What is your personal favorite ANVL component?

Darrin: Probably our Mandrel bars. It seems like a fairly simple product to design, but we spent a huge amount of time perfecting our bends. During the 3D design process we realized there was no relative consistency on how rise/upsweep/backsweep is measured on all the existing bars we analyzed. Since you can't fully rely on the listed numbers it really comes down to feel which can be greatly affected by how the bar is mounted. We tried to take all of this into account to find that sweet spot while still making it look really good and feel really balanced.

I’ve found that riders tend to be very particular about this next point, but I wonder how you feel when it comes to handlebar material: Aluminum or Carbon?

Kyle: This is a tough one to answer as i don't really believe there is a single right choice of material for everyone. As with everything there are compromises to be made. Bars made of each material feel different when riding and can have a big difference in comfort.

It comes down to having your bike flex in the places you want it. I've seen bikes with front ends that are noodly due to fork flex; if you add handlebar flex into the equation you can get a really vague feeling front end. Vice-versa, if you have too stiff of a handlebar you can end up feeling your fork flex. There’s a balance.

There's also perceptions about durability. I think historically carbon scared people because of the thinking that if carbon fractured, it would fragment everywhere and bury into your skin or something. People see a picture on the internet of a carbon bar that's broken and then freak out and swear off carbon. I would say that for people who push the hardest on their bike and ride dirty there is something to be said for using aluminum, just because there is far more history in producing aluminum bars, and the manufacturing quality variability is sometimes more controlled. You just don't see all that many high end aluminum bars breaking these days.

Carbon bars are becoming commonplace now, but I still hear stories of this or that carbon bar breaking (“just riding along” of course) and those kinds of things scare people. People aren't necessarily logical or rational when it comes to things like this. I try and understand the circumstances of failure in order to really see the whole picture.

These days people expect to be able to just crash all the time and rag-doll their bike. They’ll often just pick it up, not inspect it, and keep shredding. These are high end performance machines we're talking about. Just as with a high end car, if you crash it, you probably shouldn't just start driving it again. Most failures happen when people don't respect the machine. You get back what you put into it, as they say. Treat the machine poorly and it may bite you.

Which one of your components stands out to you as a step above and beyond the competition, and what makes that so?

Darrin: The Forge saddle. I named it the Forge due to the fact that I hand "forged" the shape from a solid block of polyurethane foam, much like the process of shaping a surfboard. It was a lot of trial and error, really studying the complex surfaces and contours. Every time I thought it was dialed I would take a little bit more away to get it as slim and low profile as possible while still maintaining the comfort. We developed the perfect density of foam, chose the best possible combination of materials for the top cover, and allowed for just the right amount of flex in the base. All of this extreme attention to detail really defined a standout product that we all run on every one of our bikes whether we're shredding our local trails, roads, or CX courses.

A number of us at the shop run some or all of these components. Aside from supporting a local company, we like these parts because they are durable, comfortable, functional, and, of course, look really rad. Read on to get all the details.

Forge Saddle

My two year old Forge Cro-Mo Saddle next to my new Ti railed Forge.

Two years ago I had the pleasure of owning a Transition Patrol, which came spec’ed with ANVL’s Forge saddle. Although it was a rad bike, I have since moved on (I get new bike fever fairly frequently), but that Forge saddle has moved on with me, going from bike to bike. You could argue that my butt has formed to sleek, fast, lines on this seat, but it goes beyond that. The CroMo railed model starts at an extremely affordable $60, and only weighs a hair more than my previous favorite, the WTB Silverado (which costs $25 more). A smart choice of materials also mean that this saddle will last; pictured here is my two year old Forge (next to the Ti railed model), which after thousands of miles of riding had only just started to lose a seam on the right rear corner.

- Cromoly, Ti, or Carbon Rails

- Leather top with Kevlar Corners

- PU Light Foam padding

- 278mmx138mm

- From $60 to $180

Swage Stem

Three different color options of the Swage stem.

The Swage is an industrial looking piece of 6061 aluminum alloy with any excess material CNC’d away, leaving only a highly refined all-mountain/enduro stem. With the return in popularity of higher rise bars, ANVL has incorporated a 5mm rise to this stem. Even if you aren’t a fan of riser bars, this will allow you to clean up the look of your cockpit by removing a headset spacer from below the stem. A widely spaced, 35mm clamp securely holds on to your handlebar, so that any flex in the system is only due to the bar you choose to run, and not the bar/stem junction.

- 6061 Alloy, CNC’d

- 5mm rise, 35mm or 50mm length

- 35mm clamp

- Black, red, blue, gray, orange

- $89.99

Mandrel Handlebar

The carbon Mandrel in front of two alloy models.

The Mandrel is offered in both carbon and alloy, in 20mm rise or 35mm rise options. With these bars, ANVL has retained a very clean, classic look, with no odd bulges or bends, and graphics. These bars will complement any bike you put them on. Check the rise and sweep of your current bars to determine see how these might feel in comparison. The alloy Mandrel comes in a slew of classy colors, and the carbon model has a much appreciated non-slip finish that will keep controls like your shifter or dropper remote from accidentally spinning around the bar at in-opportune moments.

- 7050 Alloy or UD Carbon Fiber

- 800mm width with cut-down guide-lines

- 20mm or 35mm rise

- Alloy - $89.99: Black, Red, Blue, Grey, Orange

- Carbon - $179.99: Raw finish

So there you have it; the long and short of who ANVL is, how they came to be, and the lowdown on our favorite components. If you have any specific questions about these, just let us know by leaving a comment below, and we'll get back to you as soon as we can.

Happy trails, Dan at Fanatik